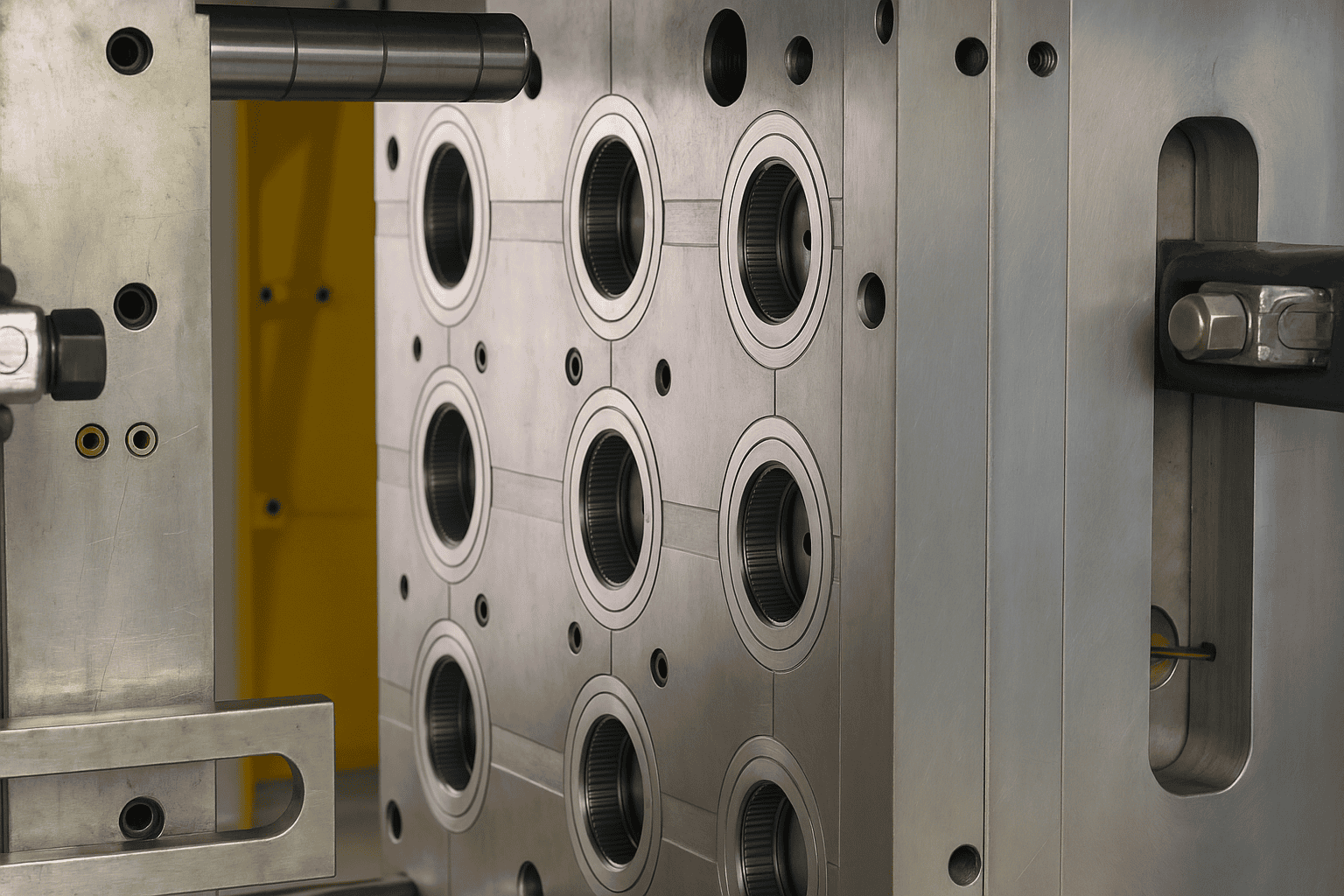

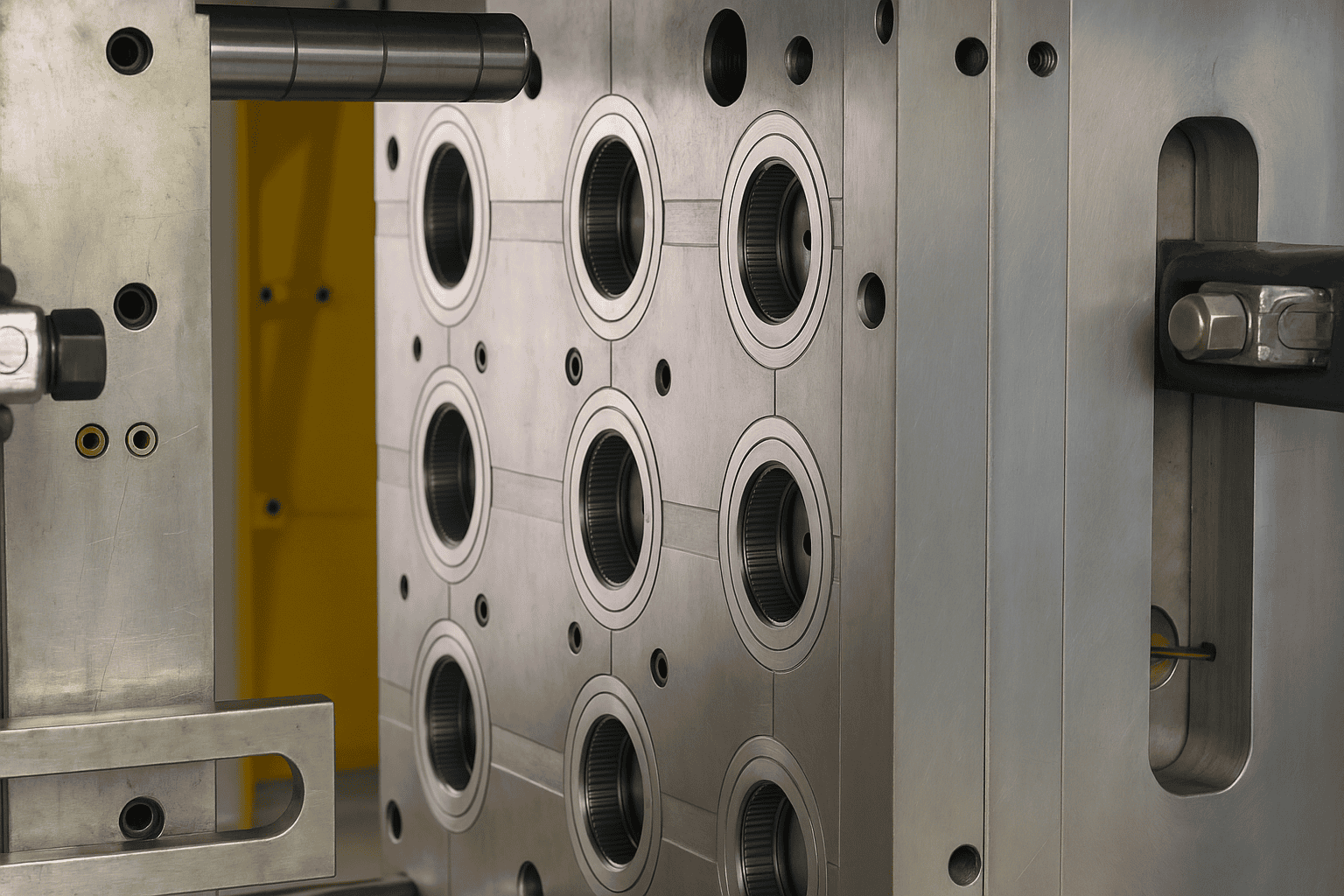

Injection Mold Base Manufacturing

Precision. Strength. Reliability.

We manufacture high-quality Injection Mold Bases engineered to meet the demanding requirements of plastic injection molding applications. Our mold bases are designed for accurate alignment, durability, and long service life, ensuring consistent mold performance and reduced maintenance.

Why Choose Our Injection Mold Bases

- Precision-machined plates with tight tolerances

- Excellent flatness, parallelism & alignment

- Robust construction for long production runs

- Suitable for standard and custom mold designs

- Manufactured as per customer drawings & specifications

Mold Base Components

Our injection mold bases typically consist of:

- Top Clamping Plate

- Cavity Plate

- Core Plate

- Support Plate

- Ejector Plate & Ejector Retainer Plate

- Bottom Clamping Plate

- Guide Pillars & Bushes

All components are manufactured with strict quality control to ensure smooth mold operation.

Manufacturing Capabilities

With advanced machining facilities, we ensure accuracy and repeatability in every mold base.

- CNC milling & drilling

- Precision boring

- Surface grinding for flatness & parallelism

- Cooling hole drilling

- Assembly & inspection

Materials & Standards

We use premium-grade materials based on application requirements:

- Mild Steel (MS)

- EN series steels (EN8, EN19, etc.)

- Alloy steel P20, C45, & H13

Mold bases can be manufactured as per HASCO, DME, IS standards, or customer-specific standards.

Applications

Our injection mold bases are used in:

- Automotive plastic components

- Electrical & electronics parts

- Packaging molds

- Consumer goods

- Industrial plastic components

Custom Mold Base Solutions

We specialize in custom injection mold base manufacturing, tailored to:

- Mold size & tonnage

- Number of cavities

- Cooling layout requirements

- Ejection system design

- Customer-specified tolerances

From prototype molds to production tools, we support your complete mold base requirements.

Quality Assurance

Each mold base undergoes thorough inspection for:

- Dimensional accuracy

- Flatness & parallelism

- Hole position accuracy

- Assembly fitment

Quality is ensured at every stage of manufacturing.