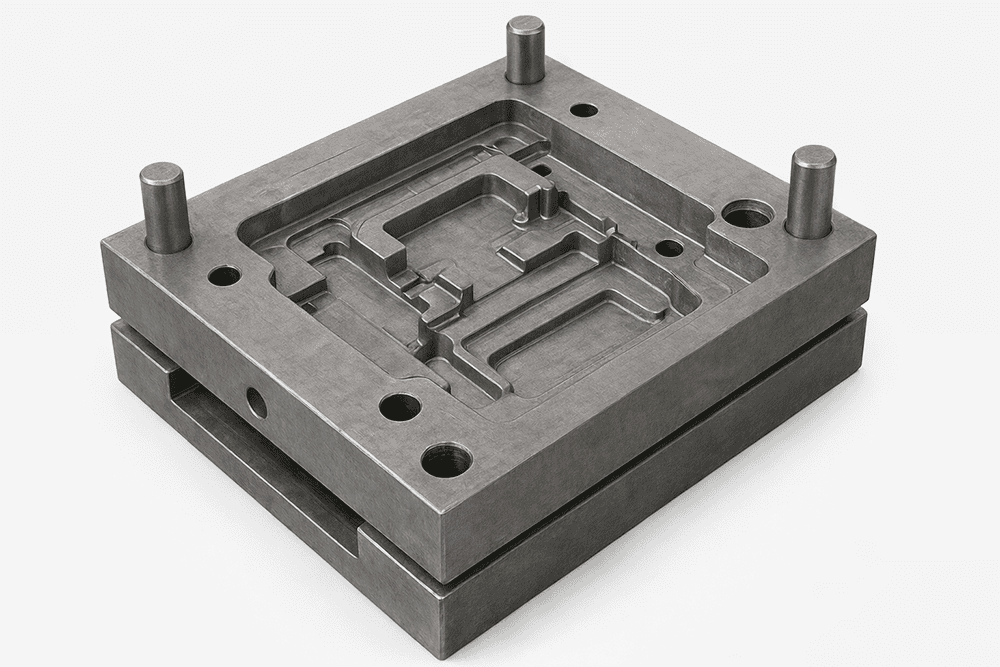

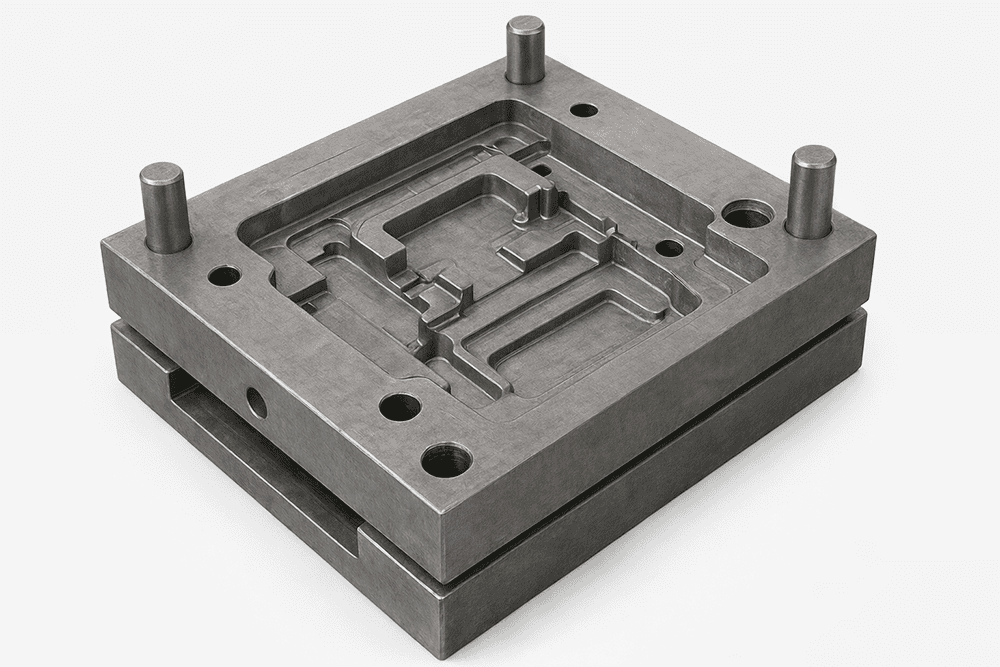

Die Casting Mold Base Manufacturing

Built for Strength, Accuracy & Long Tool Life

We manufacture high-precision Die Casting Mold Bases designed to withstand high pressure, thermal stress, and continuous production cycles. Our mold bases ensure excellent rigidity, accurate alignment, and reliable performance for both aluminium and zinc die casting applications.

Why Choose Our Die Casting Mold Bases

- Heavy-duty construction for high-pressure die casting

- Precision machining with tight tolerances

- Excellent flatness, parallelism & alignment

- Designed for long service life under thermal loads

- Manufactured as per customer drawings & specifications

Mold Base Components

Our die casting mold bases typically include:

- Fixed Platen Plate

- Moving Platen Plate

- Core & Cavity Support Plates

- Spacer / Back Plates

- Ejector Plate & Ejector Retainer Plate

- Guide Pillars, Bushes & Leader Pins

All components are manufactured with strict quality control to ensure smooth mold operation and durability.

Manufacturing Capabilities

Our in-house facilities enable us to deliver robust and accurate die casting mold bases.

- CNC milling & drilling

- Precision boring

- Heavy-duty machining for thick plates

- Surface grinding for flatness & parallelism

- Cooling and vent hole machining

- Assembly & inspection

Materials Used

We use high-quality, proven materials suitable for die casting applications:

H13 Tool Steel

- Excellent thermal fatigue resistance

- High wear resistance and toughness

- Ideal for high-pressure and high-temperature applications

C45 Steel

- Medium carbon steel with good strength

- Suitable for standard structural plates

- Cost-effective and reliable

EN Series / Alloy Steel (as required)

- High strength and durability

- Used based on application and customer specifications

All materials can be supplied with material test certificates (MTC) on request.

Applications

Our die casting mold bases are widely used for:

- Aluminium die casting molds

- Zinc die casting molds

- Automotive components

- Electrical & electronic housings

- Industrial die casting applications

Custom Die Casting Mold Bases

We specialize in custom die casting mold base manufacturing, tailored to:

- Machine tonnage & platen size

- Mold size & weight

- Ejection system requirements

- Cooling and venting layouts

- Customer-specified tolerances

From prototype tools to high-volume production molds, we support complete mold base requirements.

Quality Assurance

Every mold base undergoes detailed inspection for:

- Dimensional accuracy

- Flatness & parallelism

- Hole position accuracy

- Assembly fitment

Quality is ensured at every stage of manufacturing.

Get in Touch

Looking for a reliable Die Casting Mold Base manufacturer?

Share your drawing or requirement with us for a quick feasibility check and competitive quotation.